Voltar

ELECTROLYSIS OF CELL SUSPENSIONS

OF Bacillus subtilis (ATCC-9372) AND OF Saccharomyces cerevisiae

(FLEISCHMANN ROYALÒ ) USING CAST-IRON ELECTRODES

Orlando J. Bratfich(1), Roberto N. Domingos(2),

Dejanira F. de Angelis(1) and Ederio D. Bidoia(1) *

(1) Departamento de Bioquímica e

Microbiologia, I.B. - UNESP, 13506-900 - Rio Claro - SP,

Brazil; (2) Departamento de Física, IGCE - UNESP,

13500-900 Rio Claro - SP, Brazil

* Ederio D. Bidoia - Departamento de Bioquímica

e Microbiologia, I.B. - UNESP - Av. 24-A, 1515 - 13506-900

- Rio Claro - SP, Brazil - Tel: +55 (19) 526-4135 - Fax:

+55 (19) 534-0009

--------------------------------------------------------------------------------

ABSTRACT

Bacillus subtilis (ATCC-9372) and Saccharomyces

cerevisiae (Fleischmann RoyalÒ ) cell suspensions

were electrolyzed and the viable cell concentration was

dependent to the electrolysis time. Bacteria showed less

resistance to death than the yeast due to the differences

in cell wall composition. The electrolysis is a suitable

decontamination process to favour yeasts in relation to

bacteria.

Key words: Bacillus subtilis, cast-iron

electrode, decontamination process, electrolysis, Saccharomyces

cerevisiae

--------------------------------------------------------------------------------

Electrooxidation has been shown as a viable

alternative to biological treatments of wastewater (1, 2).

Electrolysis can reduce the number of viable cells without

the need of adding any chemical substances (3). Microorganism

growth rate can be controlled by electrolysis because one

species can have its growth rate partially or totally unchanged

while other species can be strongly affected (4).

In this work, two kinds of microorganism

suspensions, one containing Saccharomyces cerevisiae (Fleischmann

RoyalÒ , a yeast used in ethanol production processes

from sugar cane, and the other containing Bacillus subtilis

(ATCC-9372), an endospore-forming gram-positive bacterium

which is resistant to adverse conditions, were electrolyzed

with the objective of evaluating the decrease of colony-forming

units per ml (c.f.u./ml) with the electrolysis time The

electrolyses were carried out using an electrode assembly

containing 14 plates of cast iron (2 mm thickness, total

geometric area of 1109 m2) spaced 5 mm apart. A volume of

1.8 l of microorganism suspension was electrolyzed in every

trial under magnetic stirring. A DC power source (Fok Gyem

- model TR-9158/A) was used to apply a constant potential

of 15.0 V; at this voltage the current is greater than 1

A, which leads to a c.f.u./ml reduction of more than 90%

in the maximum time of 60 min. After different electrolysis

times, the electrolyte was sampled for cell counting and

to determine its conductivity, temperature and pH.

The growth conditions enumeration method

and the culture media utilized for B. subtilis and S. cerevisiae

were the following:

The suspensions (1.8 l) were prepared by

the addition of centrifuged cell pellets (4000 rpm for 10

min) in sterilized tap water. The initial viability was

2.2 x 107 cell/ml of bacteria or 7.2 x 106 cell/ml of the

yeasts (Table 1 and 2). Sterilized tap water was used as

a reference substrate for the pH and conductivity measurements.

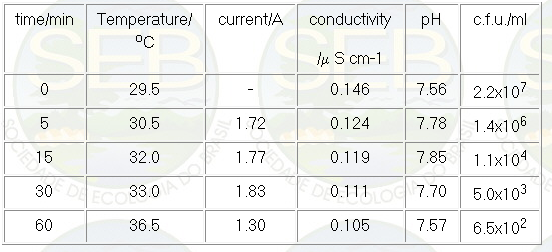

Table 1 - Data for the electrolysis of

a B. subtilis (ATCC-9372) suspension at 15.0 V.

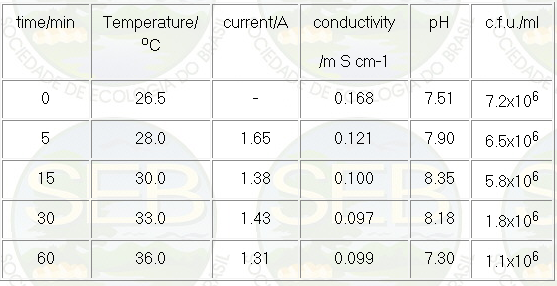

Table 2 - Data for the electrolysis of a S. cerevisiae

(Fleischmann RoyalÒ ) suspension at 15.0 V.

. The B. subtilis (ATCC-9372) cultures

were grown in nutrient broth (3 g of beef extract, 5 g of

peptone in 1 1 of water) at 150 oscillation/min during 24

h and pH = 7.0. The bacillus cells were quantified as c.f.u./ml

by PCA (plate count agar) using the technique of pour plate

after incubation for 72 h at 360 C to determine the viable

total-cell counting.

· Pure yeast cultures of S. cerevisiae

(Fleischmann RoyalÒ ), a non-flocculating strain,

were grown in a YEPD broth (10 g of yeast extract, 20 g

of peptone, 20 g of dextrose in 1 1 of water) at 150 oscillation/min

during 24 h and pH = 6.5. The yeast cell counting number

was determined as c.f.u./ml in YEPD agar (YEPD broth plus

18 g of agar) using the technique of pour plate for 72 h

at 300 C.

As shown in Table 1, about 94% of the B.

subtilis (ATCC-9372) cells could not be recovered in the

plate count after 5 min of electrolysis. On the other hand,

the yeast (S. cerevisiae - Fleischmann RoyalÒ ) showed

a higher resistance to electrolysis, since only 10% of the

individuals died after 5 min of electrolysis (Table 2).

Probably, this difference in resistance to death from electrolysis

is mainly due to the different composition of the cell walls

of the two microorganisms. Considering that the conductivity

and pH have not changed significantly (great changes in

conductivity and pH could diminish the cell viability of

the suspensions), the main cause of the decrease in the

cell viability was the electrolysis time. Furthermore, electrolysis

causes the yeast to flocculate, despite it being a non-flocculating

strain (the flocs consisted of dead cells with some live

cells trapped inside, which was observed using erythrosin

dye); this should be caused by changes in the superficial

charges around the yeast cell wall during the electrooxidation.

The B. subtilis cells, on the other hand, did not flocculate

and the electrolysis was efficient to kill most of the cells.

In conclusion, these results indicate that electrolysis

might be well suited as a decontamination process to favour

yeasts (fungi) in relation to bacteria.

--------------------------------------------------------------------------------

RESUMO

Eletrólises de Suspensões

de Bacillus subtilis (ATCC-9372) e de Saccharomyces cerevisiae

(Fleischmann RoyalÒ ) Utilizando Eletrodos de Ferro

Fundido. Suspensões celulares de Bacillus subtilis

e Saccharomyces cerevisiae foram eletrolisadas e observou-se

que a concentração de células viáveis

era dependente do tempo de eletrólise. B. subtilis

mostrou-se menos viável que S. cerevisiae após

tratamento eletrolítico provavelmente devido a diferenças

na composição da parede celular. A eletrólise

atua como um processo de descontaminação de

bactérias em suspensões contendo leveduras.

Palavras-chave: Bacillus subtilis, eletrodo de ferro, eletrólises,

processo de descontaminação, Saccharomyces

cerevisiae.

--------------------------------------------------------------------------------

REFERENCES

Genders, J. D.; Weinberg, N. Electrochemistry

for cleaner environment. Electrosynthesis Co, East Amherst,

1992.

Patermarakis, G.; Fountoukidis, E. Disinfection of water

by electrochemical treatment. Water Research, 24: 1491-1496,

1990.

Tokuda, H.; Nakanishi, K. Application of

direct current to protect bioreactor against contamination.

Bioscience Biotechnology Biochemistry, 59: 753-755, 1995.

Karba, R.; Gubina, M.; Vodovnik, L. Effects of direct electric

current on the growth of microbes and their susceptibility

to antibiotics. Bioelectrochemistry and Bioenergetics, 30:

173-180, 1993.